Engineered Solutions for Silo Cleanout Problems Worldwide

The Problem:

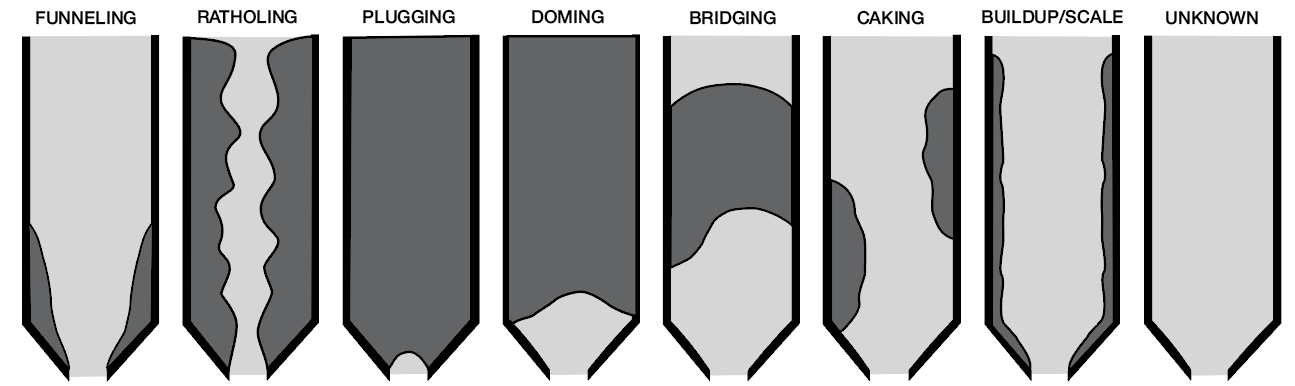

Virtually any silo or bulk storage vessel can suffer from bridged, arched, ratholed, lumpy or hydrated material. These problems are almost unavoidable given the wide range of variables resulting from the many different types of silos and the numerous types of materials that are stored in them.

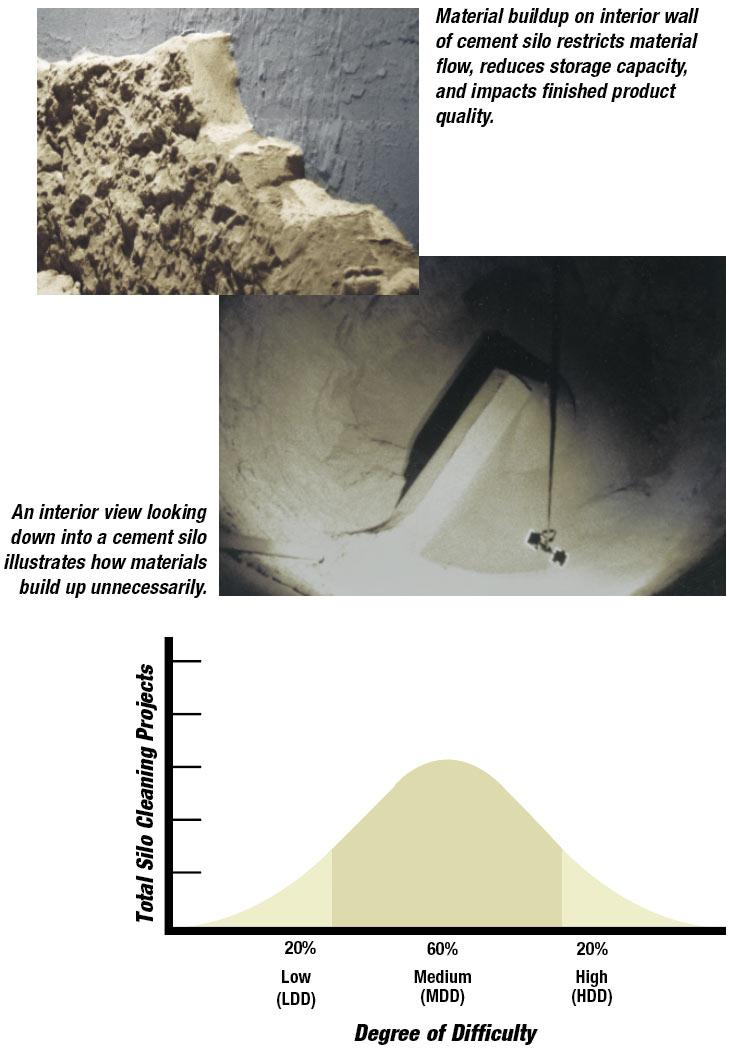

Unfortunately, once these problems occur, productivity at the plant is negatively impacted in a progressively more serious way each day the unwanted material buildup is allowed to continue. Inefficient material flow, reduced storage capacity, and quality control issues can have an immediate impact on the profitability of a plant.

Every Cleanout Project Is Different

With literally scores of materials from cement to coal to chemicals to grain being stored in bulk storage facilities around the world, no two silo cleanout projects are the same. MOLE•MASTER breaks these types of projects down into three categories: low degree of difficulty, medium degree of difficulty, and high degree of difficulty.

The graph on the right illustrates the different levels of difficulty encountered when cleaning out or unclogging silos. A typical bell curve illustrates that approximately 60% of the projects fall into the medium degree of difficulty (MDD) level while the other 40% fall into either the low (LDD) or high degree (HDD) of difficulty level.

LDD projects are sometimes handled manually by the plant’s maintenance crew. MDD projects typically require equipment such as the Junior™ 360° or ARCH•MASTER™ which can be provided by MOLE•MASTER as a turnkey service or purchased or rented for a specific project. HDD projects require the ultimate level of experience and safety that can only be accomplished by highly trained technicians who have completed these types of projects in the past. MOLE•MASTER’s Big MoleSM System is the only turnkey service available to handle HDD projects on a reliable and consistent basis.

Mole•Master Has The Right Cleanout System For Every Silo

The Solution:

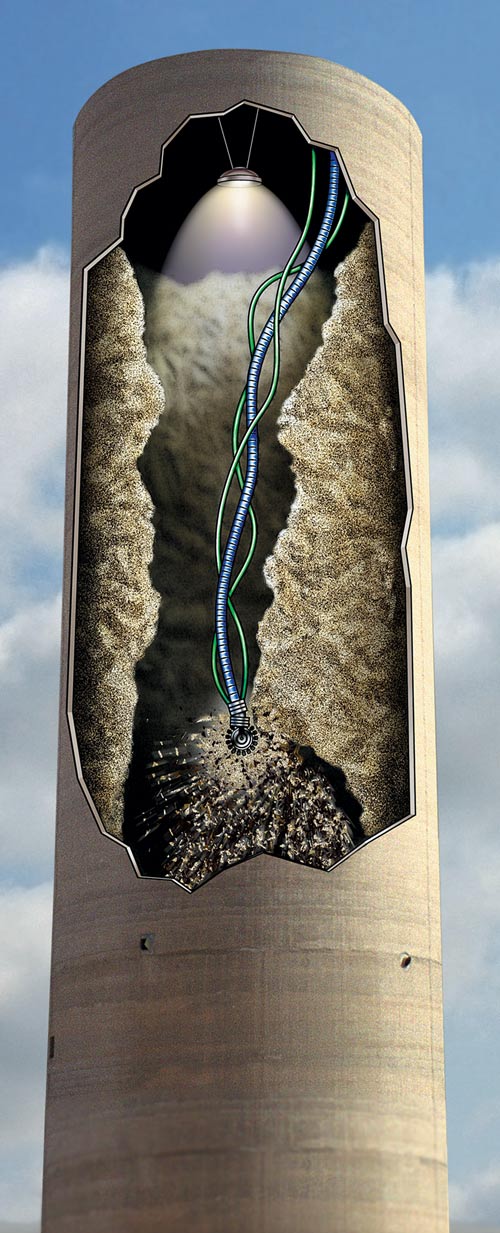

For Truly Tough Projects, Nothing Surpasses The Big MoleSM System

High Degree of Difficulty projects generally involve the storage of cement, coal, limestone, gypsum, clinker and pelletized or hydrated lime and other hygroscopic bulk solids. Flow problems involving these types of materials can only be solved using the proprietary technology of the Big MoleSM System. Once MOLE•MASTER is on the job, we handle everything from initial planning to project execution to final demobilization using our professional project management approach. This total turnkey service assures that nothing is left to chance. Our team does not leave until your silos are clean and restored to planned storage capacity.

Big MoleSM System Benefits

- Versatile—We work on any type of bulk storage vessel, no matter what type of material is being stored and no matter how long the material has been non-flowing.

- No Human Entry Required—No danger of injury due to collapse of stagnant material. All equipment is controlled remotely from the silo roof. We use NO chemicals and NO explosives. There is no chance of contaminating stored materials or damaging the vessel.

- Total Material Recovery—In virtually every instance, valuable material is freed and readied for further processing or loadout, as required.

- Lost Storage Capacity Is Recovered—Storage vessels are restored to 100% of their planned capacity.

- Downtime Is Minimized—The Big MoleSM System is so efficient that jobs that previously took weeks or even months now take only days. Less downtime. Lower cost.

- 100% Dry Process—No water or other liquids are used. Therefore, there is no water damage to the material or facility. No mess. No mud. No expensive cleanup.

- Non-Sparking Equipment—The Big MoleSM System utilizes unique non-sparking equipment which is mandatory for potentially hazardous environments such as grain and coal storage facilities.

- Preventative Maintenance Programs—MOLE•MASTER offers routine maintenance programs tailored to the needs of your plant. Preventative maintenance can help avoid emergency call outs for clogged bulk storage and process vessels.

Safety Is #1

All MOLE•MASTER technicians are MSHA 5000-23 certified and trained to comply with all current OSHA standards for maintaining a completely safe work environment. Our in-place safety program includes comprehensive policies covering Confined Space Entry, Lockout/Tag Out, Hazard Recognition and Right-To-Know. With our remote technologies, unsafe silo entry is eliminated.

The MOLE•MASTER Guarantee

MOLE•MASTER Services Corporation provides the highest quality professional services available, utilizing our highly trained professional technicians and the most technologically advanced equipment in the service industry today. This unique combination of manpower and equipment assures you of the safest and most cost-effective solution for any unwanted material buildup problem.