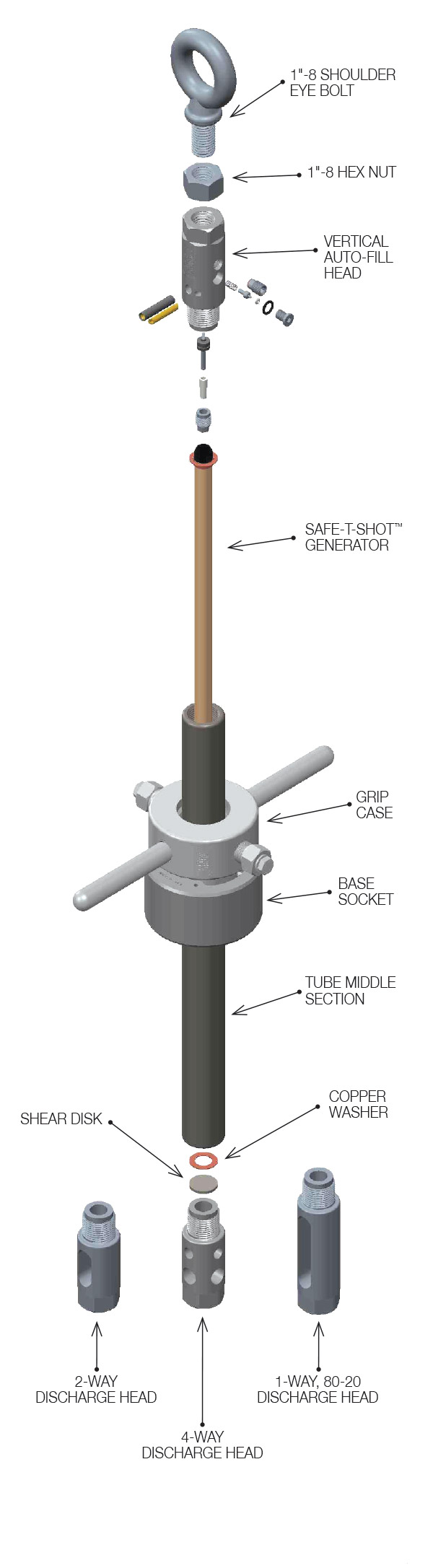

Safe-T-Shot Build-Up Removal System

On line build-up removal system

From the industrial Cleanout Specialists… Mole•Master™ introduces Safe-T-Shot™

Removing build-ups and keeping material flowing in a typical cement plant’s kiln system—especially while they are on line—is a critical need throughout the cement industry. Whether the problem exists in silos, pre-heater towers, conditioning towers, by-pass ducts, coolers, feed pipes or riser ducts, Safe-T-Shot™ is a proven solution ready to get the job done. As a user of the cardox method in our turnkey industrial services for over 30 years, no company is more knowledgeable about the benefits of using a safe, build-up removal system than Mole•Master. Now Mole•Master is using its three decades of manufacturing expertise to produce this product at its plant in Marietta, Ohio, USA.

The Benefits of Using Mole•Master Safe-T-Shot™

- Highest quality product that meets or exceeds all governmental regulations

- Works quickly, efficiently, safely and economically

- Virtually eliminates “rings” and “chokes” in your rotary kiln

- Effectively dislodges hardened build-up in pre-heater towers, silos and process vessels

- Does NOT contaminate your material

- Eliminates as much as 3 tons of material in a single shot

- No confined space entry required

- Designed and manufactured in the USA

- A Service, Training and Maintenance Program designed to assure that your Safe-T-Shot™ equipment is always tested and ready to perform at a moment’s notice

- Competitive pricing

Safety is #1

- MSHA part 46 & 48 trained personnel

- Able to respond quickly to emergency situations from multiple locations

A New Level of Service

- Mole•Master has over 30 years of experience and our team has a combined 350 years of experience as a user of this technology

- Mole•Master has been licensed by the ATF to Manufacture, Distribute and Use this technology

- NO Supply Chain Interruptions

- Inventory of operating material located in Ohio (one-day service in most cases)

- Operating material carries a USDOT non-hazardous/non-explosive rating

- Complete systems, parts, testing (INCLUDING ON-SITE), re-certification, training, installation and service available

- Firing head rebuilding and tube inspections all done in-house at our Marietta, Ohio, USA headquarters

- Straightening service available—extends service life of tubes

- In-house machine and welding shop

- Loaner pump program available for emergencies

About Mole•Master™

Mole•Master combines expertise in both manufacturing and service to provide turnkey solutions to industrial plants of all types and sizes.

Since 1986, Mole•Master has been an industry leader in providing safe, reliable, cost-effective industrial services ranging from silo and bin cleaning to structural inspections, pipe cleaning, vacuum services, hydro-blasting, media blasting and cardox method blasting like Safe-T-Shot™.